What PrintWatch has achieved to date offering only spaghetti detection

Get ready to rest easy knowing PrintWatch will be able to detect a wide variety of defect types, professionalize your 3D printing game with our latest BETA signup for enhanced failure support!

Don’t you hate it when you start a long print and come back after a few hours to realize its ruined because it lifted from the bed or it became a stringing nightmare. Luckily, thanks to PrintWatch you can now get notified and stop the print immediately after a defect occurs, giving you the chance to restart your print and save valuable time. At printpal, we’ve been hard at work adding support that actually detects these failures.

Sign up for our BETA program now or get PrintWatch TODAY and be among the first to access these upcoming features!

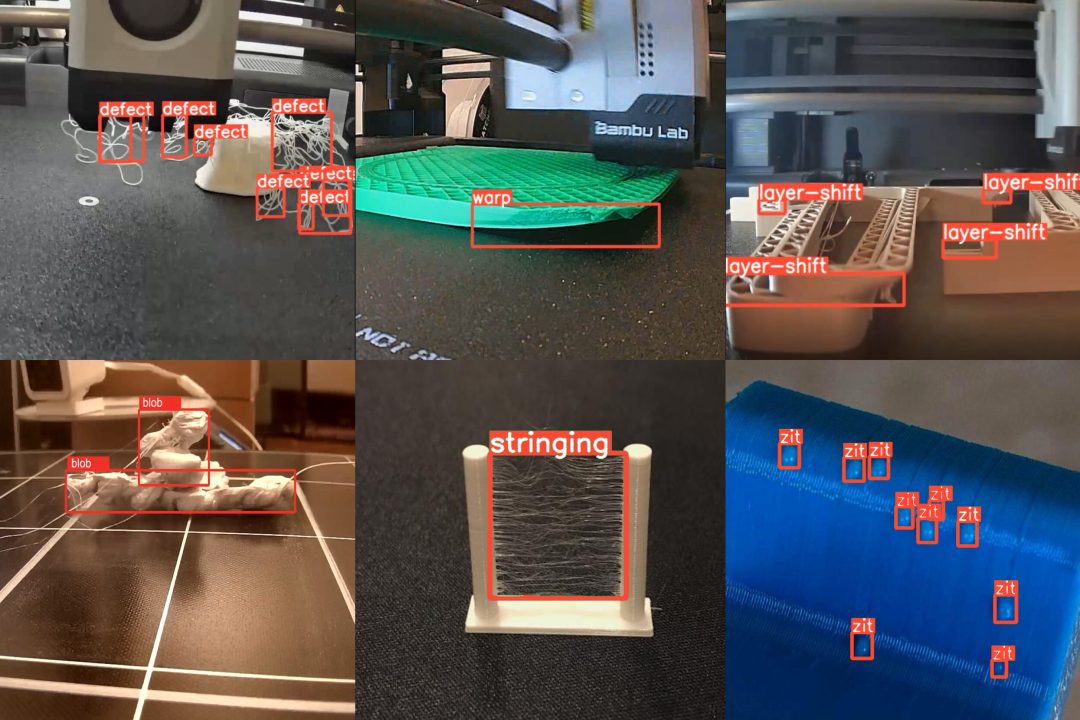

Layer Shifting occurs when the layers of a 3D printed object misalign during the printing process, creating a noticeable step or offset that can significantly affect both the aesthetic and functional quality of the print. This error can be caused by various factors, including mechanical disturbances, improper printer settings, or issues with the printer’s hardware, leading to a disruption in the print’s continuity and precision.

PrintWatch will now be able to tackle this challenge head-on. Our latest feature employs AI to monitor prints in real-time, detecting layer shifts the moment they happen. With PrintWatch, ensure your creations are precise and flawless, as we empower your printing process to catch layer shifts instantly, allowing for a prompt and comprehensive response.

Spaghetti is the most common defect that occurs in 3D printing and it happens when the printer continues to extrude filament without adhering to the intended layers or pattern, resulting in a tangled mess of filament strands resembling spaghetti.

This issue typically arises when the print detaches from the build plate or when there is a failure in the print process, leading the printer to extrude filament aimlessly. The outcome not only wastes material but also requires cleanup and restart of the printing process, highlighting the importance of consistent monitoring and calibration of the 3D printer to avoid such mishaps.

PrintWatch is already capable of successfully identifying when these defects occur, giving real-time notification of the failure and giving users peace of mind when printing.

The full failure extension of PrintWatch will support all of the possible failures one might experience with a 3D printer. Below are a few examples of failures we can detect using the latest trained version of our model.

Interested in implementing our AI into your current or future product? If so, please reach out here or get in touch at info@printpal.io