Artificial Intelligence Monitoring in 3D Printing

The 3D printing industry continues to push the bounds of innovation, enabling individuals and businesses to transform their digital designs into tangible objects with unprecedented ease. However, the inherent complexity of the 3D printing process often leaves room for defects and failures, resulting in process inefficiencies, waste, and deceleration of the adoption of 3D printing technology. To address this challenge, cloud-based Artificial Intelligence (“AI”) systems have been developed to monitor 3D prints in real time, detecting defects and potential failures with remarkable accuracy. This paper explores the transformative potential of employing cloud AI systems to monitor 3D printing projects, ensuring enhanced quality control, improved efficiency, and enabling cost savings.

3D Printing & AI Monitoring Background

Over the past decade, 3D printing technology has experienced a significant surge in popularity across various industries, such as manufacturing, healthcare, aerospace, and automotive. The ability to rapidly create complex geometries and customized objects has revolutionized the prototyping and production processes. Despite the advancements in hardware and software, 3D printing remains susceptible to defects and failures that can undermine the efficiency and reliability of the process.

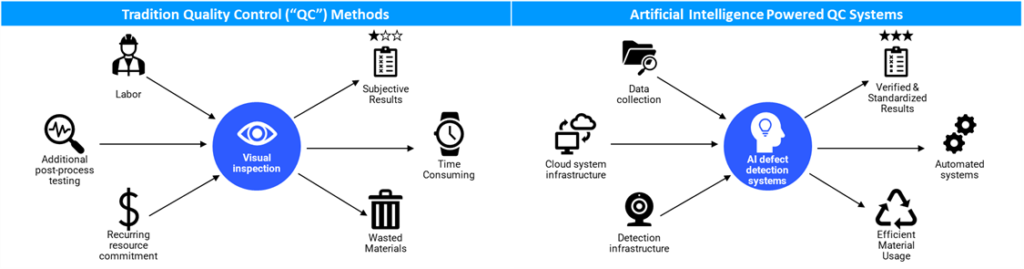

Traditional quality control methods for 3D printing have historically relied on visual inspection, which is time-consuming, subjective, and prone to human error. These methods cannot detect defects or failures in real-time, resulting in wasted materials, scrapped prints, and delayed production schedules. As a result, there is a growing need for a proactive monitoring system that can identify potential issues during the printing process, allowing for timely intervention.

In the following sections of this article, we will explore the key benefits and features of cloud AI systems for 3D print monitoring. We will delve into the technical aspects, including data collection and analysis, anomaly detection algorithms, and real-time alerts. Additionally, we will discuss the implications of adopting such systems, ranging from improved print quality and reduced waste to enhanced productivity and cost savings. The future of 3D print monitoring lies in the hands of AI systems, and this article aims to shed light on their transformative potential in revolutionizing the 3D printing landscape.

Machine Learning Background

To understand AI systems at a basic level and how they work, it is essential to understand how Machine Learning (“ML”) models operate and what they do. A classifier ML model analyzes data representing the characteristics of a 3D-printed object and categorizes it into different failure classes. The ML model learns patterns and features indicative of various failures by being trained on labeled datasets. Once trained, the model can assess new prints and assign probabilities or confidence scores to each failure category. The trained model enables users to identify specific issues and take appropriate and timely corrective actions. This automated approach streamlines the identification and classification of printing failures, improving overall print quality and resource utilization.

Localization in ML is the process of identifying and precisely locating specific objects or features within an input image or dataset. It is crucial for various applications, including computer vision and object recognition. In the context of 3D printing failure detection, localization models are used to pinpoint the exact locations of defects or anomalies within a printed object. These models employ techniques such as bounding box regression, where the model predicts the coordinates of a bounding box that tightly encloses the identified defect. By training on labeled datasets containing images of successful and failed 3D prints, the localization model learns to identify and localize print defects. This localization information provides valuable insights to users, allowing them to precisely assess the severity and location of printing failures, aiding in efficient defect analysis and subsequent corrective actions.

Building Comprehensive Machine Learning Systems

To effectively track and monitor defects over time, we create a comprehensive system of ML models that combines pre and post-processing algorithms. Pre-processing algorithms enhance and prepare input data before being fed into an ML model. These algorithms may include image filtering, noise reduction, or image normalization techniques to optimize the data quality and remove any unwanted artifacts that could affect the defect detection accuracy.

Post-processing algorithms refine and analyze the output of the ML models. They handle tasks such as anomaly detection, clustering, or trend analysis to identify patterns and changes in defect occurrence over time. These algorithms help by distinguishing between intermittent or sporadic defects and persistent or recurring issues. By tracking and analyzing these defects, ML models can identify trends and correlations, allowing users to implement proactive measures that prevent or mitigate future failures.

- Anomaly Detection: Using labelled or un-labelled data, a model can detect anomalies in a machine, piece of hardware, or process. Anomaly detection in 3D printing monitors the machine’s health in real time, which allows for scheduling preventative maintenance, and can identify process-level anomalies slowing down production.

- Clustering: Identifying data that are similar to each other is done by clustering. Through this process, various anomalies are grouped together to identify a part or location in the process that is causing an issue.

- Trend Analysis: Monitoring the occurrence of anomalies or defects is known as trend analysis. Observing the trends gives insights about when a machine may fail and allows for proactive maintenance. Trend analysis provides insight into how process-level KPIs or variables will perform in the future.

Combining pre and post-processing algorithms creates a comprehensive defect-tracking and monitoring system. It enables continuous assessment of the printing process, identification of defects, and analysis of their evolution over time. This holistic approach provides valuable insights into the underlying causes of failures, facilitates process optimization, and ultimately contributes to enhanced print quality and productivity.

Impact of AI-Powered Defect Detection

Integrating cloud AI systems for monitoring 3D prints impacts multiple aspects of the printing process, such as providing significant cost, material, and time savings. By embracing AI systems, the entire industry benefits from increased optimization and efficiency, leading to greater adoption of 3D printing capabilities.

- Cost Savings: Traditional methods of quality control that rely on manual inspection can be labor-intensive and time-consuming. Implementing AI defect monitoring reduces labor costs by reducing or eliminating manual inspection needs. Furthermore, the early detection of defects allows for prompt intervention and corrective measures, minimizing the need for costly reprints or post-processing.

- Material Savings: 3D printing often involves using expensive materials with failed prints resulting in wasted resources. Cloud AI defect monitoring systems help mitigate material waste by promptly identifying and addressing defects during printing. When a defect is detected, the print is stopped, minimizing the unnecessary consumption of materials, leading to a more sustainable and cost-effective approach to 3D printing.

- Time Savings: Real-time monitoring ensures immediate detection of defects and failures during printing, enabling timely intervention and corrective action that reduces the time spent on unsuccessful prints. By optimizing printing, AI systems significantly improve production efficiency and accelerate the overall time-to-market for 3D-printed objects.

The combined impact of savings from AI-driven monitoring is transformative for the industries utilizing 3D printing technology. A wider adoption of AI systems in 3D printing facilitates faster and cost-effective prototyping, enabling innovation and experimentation across sectors.

Beyond the immediate benefits to businesses, AI-driven monitoring also contributes to a more sustainable and eco-friendly approach to manufacturing. Reductions in material waste and energy consumption associated with failed prints directly align with environmental goals, fostering a more responsible and efficient use of resources.

Transforming 3D Printing Through Artificial Intelligence

These AI systems offer real-time, automated defect detection and monitoring capabilities by utilizing object detection, classifier ML models, and pre and post-processing algorithms. Integrating these defect monitoring systems represents a transformative milestone for quality control and production efficiency in 3D printing. The influence of AI-driven print monitoring is far-reaching, with tangible impacts such as a reduction in labor costs, minimized material waste, and accelerated production timelines. Adopting these AI systems will propel innovation, enabling faster prototyping and experimentation, transforming the 3D printing industry, and furthering its widespread adoption.