PrintWatch Official Release

Chicago, Illinois, United States — January 26, 2022 — printpal.io (“printpal” or the “Company”) is pleased to announce the official launch of the PrintWatch software and API used for monitoring 3D print jobs in real time using Artificial Intelligence.

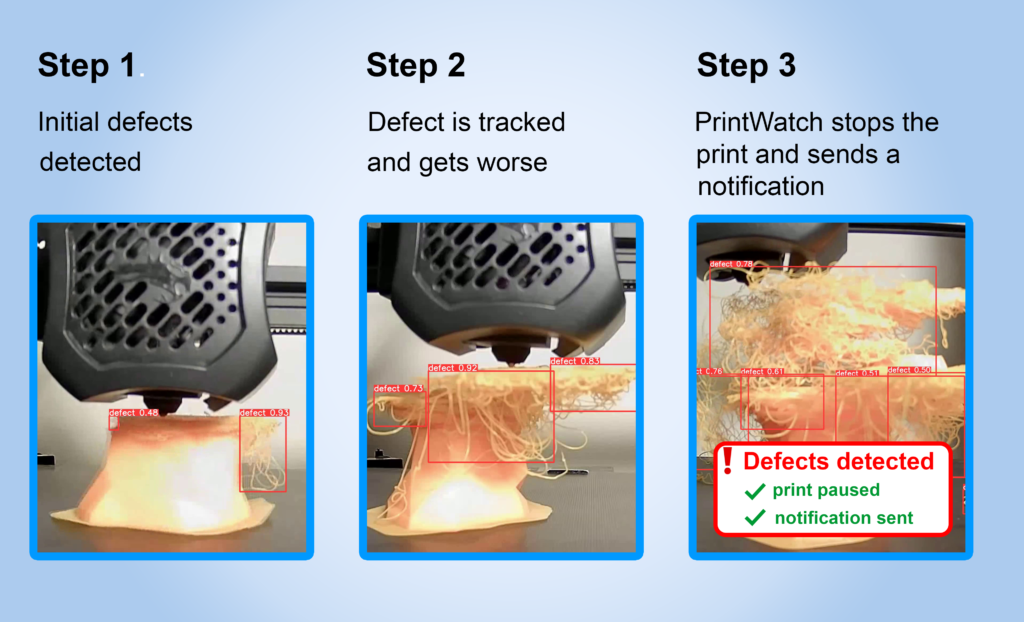

PrintWatch is a software and API that will monitor 3D prints in real-time to detect defects that begin to develop during a print job. When the software detects a defect, it tracks the defect and if it gets worse, actions are taken. Some of the actions include stopping the print, turning off the heat, and sending a notification to the owner of the printer. These actions prevent the printer from continuing a defective print for hours, and the user is notified right away. This saves time and material in addition to reducing the risk of damage or fire to the printer and its surroundings.

In addition to detecting defects in real-time, PrintWatch has an Anomaly Detection System running in the background. The Anomaly Detection System detects and flags anomalies in a printer. The system can detect very subtle issues so the user can schedule maintenance for the printer to reduce downtime. For example, the system may be able to detect there is something slightly wrong with one of the axis of a printer and signals the user to check on the printer.

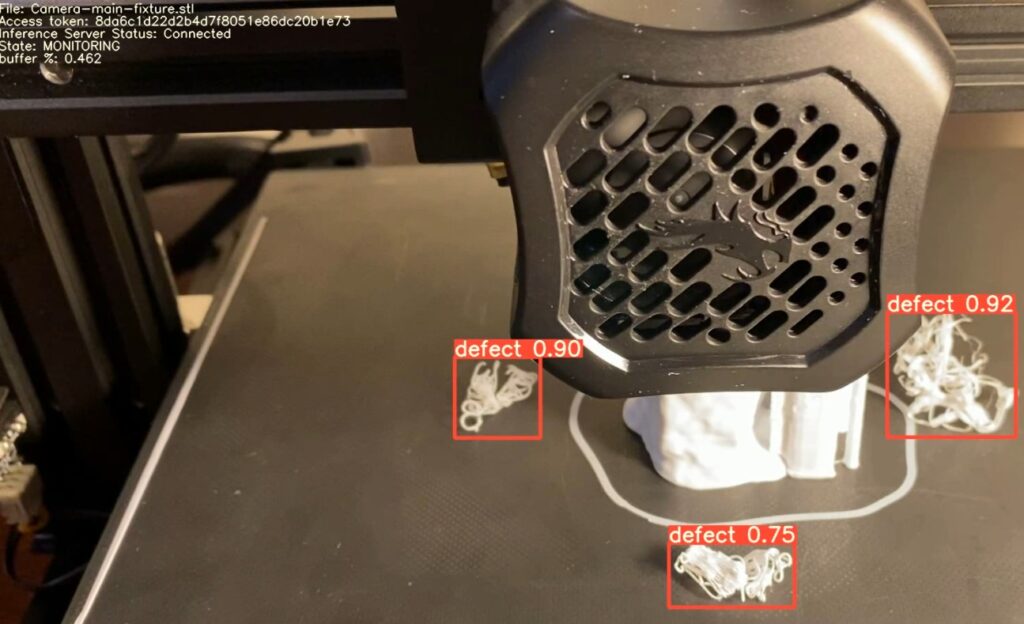

In order to detect defects in real-time, PrintWatch takes the video stream of a camera fixed onto the printer’s print area and runs it through a Machine Learning model that can detect defects of various sizes, shapes, colors, materials, lightings, and settings. When a defect is positively identified, PrintWatch then begins to track the defect to see how it develops. If it is clear that the defect is getting worse, PrintWatch takes action. This tracking system helps prevent any false-positives from triggering action from the software.

PrintWatch runs the computationally heavy Machine Learning models on the cloud meaning any device with internet is able to access the API. Run the software with as little as a Raspberry Pi Zero. PrintWatch is made easily available via OctoPrint as a plugin which can be found here. Additionally, users may create a custom integration of PrintWatch for builds that are not using OctoPrint in less than 5 lines of python code.

A locally running version of PrintWatch is being developed and tested giving the user the ability to run PrintWatch in house without having to connect to the internet. This is best suited for larger print operations or industrial settings where the user may have security concerns. It is built to run on any CUDA enabled devices, including the NVIDIA Jetson platform. The product is extremely scalable and can service any amount of printers.

Find out more about PrintWatch by visiting our website.

About printpal.io

printpal.io is a Chicago based technology company that specializes in Machine Learning and Artificial Intelligence. By applying state of the art technology to real-world problems, printpal.io makes life easier for all. The Company is dedicated to sustainability and reducing waste — this means coming up with the most efficient way to do something and reducing waste of resources when it comes to 3D printing defects.

The Company is pursuing development of other software and systems that include:

- Optimizing the speed and quality of a 3D print by analyzing the G-Code and feedback data from the printer

- Inference API for Computer Vision models or GitHub repositories that detect any object

- E-commerce integration for 3D printers that allows users to print files

For further information, please contact:

- Peter Lebiedzinski, Chief Executive Officer of printpal.io, lebiedzinskip@printpal.io